|

Veneer

is a very thin sheet of some material that has been

sliced off of a big chunk of that material and used as a facing. Wood

veneer a thin sheet of wood sliced off of a log. Decorative veneers are

shaved off in sheets by shoving a log along a very big knife a peeling

off the slice like an apple peel.

Veneering is the

process of laminating that sheet to a strong backer of another

material. In the case of wood veneering there are two powerful advantages to this type of

manufacturing. The first is to make otherwise very expensive woods

affordable (a log goes alot further when it's sliced really thin), but

more importantly the process of laminating wood (a material that

breaks, splits, expands, and is an otherwise ornery and dimensionally

unstable material) to a stable and strong backer makes the wood stay

put and not crack or distort over time. Much high quality woodwork (pianos, for example) is veneered. Veneering capability is

essential in any interiors fabrication shop.

|

Below are some images of veneer work that we've built.

|

Flat veneering

Everyone has interacted with flat veneering - plywood is the

most common example, in which layers of veneer are laminated together

to make a thick sandwich. You can veneer anything - you just have to

use the

right glue. For example, very thin shelves that must carry alot of

weight can be made by veneering steel plates with decorative wood

veneers. Veneer doesn't have to be wood - metals can be laminated to

plastics, plastics to wood, wood to glass, glass to metals. But in

order to get away with this type of innovation a deep understanding of

the characteristics of the laminate, the substrate, and the adhesive

that glues them together is essential. All materials change dimensions

back and forth over the course of a year but some with heat, some with

moisture, some with pressure, some with age; all materials have their

own cohesive and adhesive properties each being unique and the adhesive

must be designed with both adherends taken into account. |

|

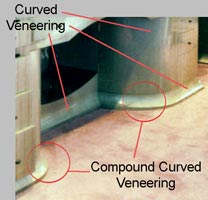

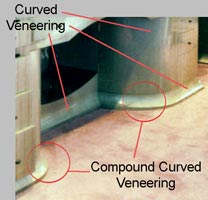

Curved veneering

Veneering involves pressure (to press the sheet to the shape of the substrate)

and holding time (to hold it there until the glue cures). Veneering

flat sheets just need another flat sheet with some clamps. Curves need

an opposite curve to clamp it in place.

|

|

Compound-Curve veneering

This is not easy - veneer is rigid, like a sheet of paper. It's

difficult to lay a sheet of paper down on a globe or some portion of

one because it has to "stretch". But, with

some veneers it's possible to slice, inlay, slice again, inlay again,

and then soak and press it down on a compound curve and make it look

like it was carved out of solid wood. This photo shows a part of the

piece where flat, curved, and compound-curved veneering all takes

place. This was required because the veneer (English Harewood) is not available in solid wood form.

|

|

|