|

Wood joinery

is the process of creating a physical interlocking shape at the joint

where two pieces of wood are held together. Dovetails are an example of

this, but there are many different types of joint design in wood

joinery. These designs were developed long ago when glues were

unreliable - they were not particularly strong and they were made from

natural material (hide-glue, for example) that was eaten by microbes

and fungus that over time that left the "glue joint" without any glue

and the two pieces of wood fell apart. Glues today are very strong and

last a long time.

However, all woods share a classic glueing characteristic

- glue sticks very well to the side-grain of wood, but does not stick

very well to the end-grain of wood. So, every wood joint is designed

with this in mind: maximize the side-grain contact of one piece with

the side-grain of the other piece.

All of the classic joint designs very effectively do this.

|

Below are some images of wood joinery work that we've built.

|

This is a typical dovetail joint design in Walnut. No glue would hold

these boards at right angles if they were simply butted together with

some glue. Interlocking these boards with dovetails not only maximizes

the amount of side-grain surface area contact between the two boards,

but creates a wedge-style interlocking joint that holds even without

glue. With glue in the joint, if the unit is put under stress the

boards themselves will break long before the joint comes apart.

|

|

This is another example of dovetail joinery, this time in Elm. This

joint is between two boards that are more than 24 inches wide. The

joint is exceedingly strong (like the example above) and it also allows

both boards to expand and contract across the grain over the course of

the year so no cracks or splits appear in the piece.

|

|

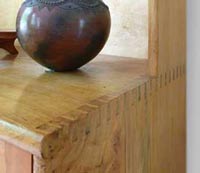

A closeup of the joint in the piece above. As you can see, because the

dovetails interlock, they create a pleasing visual pattern. Joint

designers long ago designed what is called a "blind dovetail" joint in

which a thin flap of wood is left on each board that covers the actual

joint of the board being joined to it, retaining the strength of the

dovetail joint, but the look of a miter joint in which the dovetails are masked by the flap. Just one of the many

different variations of joint design that maximizes side-grain to

side-grain contact between boards.

|

|

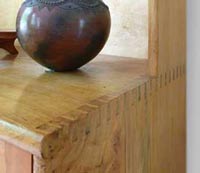

A closeup of another portion of the joint in the same piece.

|

|

|

|